Industrial IoT

A global ultrasonic welding manufacturer asked ICS for assistance designing an updated interface for its next-generation welder, which is used to manufacture products from automobiles to consumer electronics.

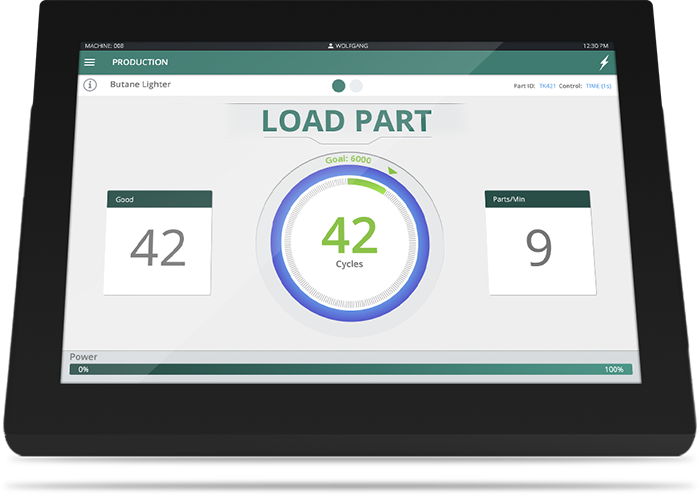

Our client wanted a unified human-machine interface (HMI) design that spanned five embedded and mobile devices, and satisfied the needs of four user personas.

Challenge

The interface had to clearly display detailed information on a number of specific tasks, including weld creation, production, data analytics and troubleshooting, and the visual design had to mimic the company's industrial design.

Project

Completion

21 weeks

Deliverables

- Information architecture

- Wireframes prototype

- Pattern library

Methodology

- Design sprints

- Test early & often

- Material design

Using two-week design sprints, we broke the complex design project into five phases: understand, diverge, converge, prototype and test.

To better understand how their users interacted with the company's existing products, our client spent a year conducting in-depth research. With this critical insight, as well as client input regarding the categories and tasks most in need of design solutions, we went to work.

We started by dividing the four main personas into tasks, traits, habits, motivations and technological experience, and reviewing the ways the five different devices would be used. We also listed user challenges and opportunities, which helped us identify and address pain points.

We integrated data analytics throughout the system so users could instantly create a report based on the real-time, parsed information they were seeing at that moment.

We created an intuitive and unique way to develop recipes because engineers said they wanted to view data and edit weld parameters. To make this a reality, we created a bank of parameters that allowed users to first set necessary parameters, such as control modes or suspect and reject limits, and later add others as needed.

After reviewing extensive research and test results, we created a simplified dashboard that was easy to read and met the needs of all personas. For instance, we stored parameters, including access to critical analytics, in a sliding drawer on the right side of the screen. We reserved the center of the screen to feature weld results, and displayed the weld history on the left.