Miller Electric Mfg.

Revolutionizing the Welding Industry

ICS and Miller Team Up to Develop Cobot Welding Automation System

Miller Electric Mfg. LLC came to ICS with an ambitious vision: democratize robotic welding for small shops. It was an inspiring goal — and a timely one. The welding industry faces a growing shortage of skilled professionals, and while AI and robotics offer a promising solution, most systems remain overly complex, unintuitive and tailored for large-scale manufacturing environments like automotive plants.

Identifying an underserved market, Miller aimed to create a collaborative robot (cobot) welding system designed to simplify automation for shops and welders new to robotic technology. Unlike systems that replace human workers, Miller envisioned a cobot that would work alongside them, automating repetitive tasks while allowing skilled welders to focus on more complex work.

"One of the things we're most proud of with the Copilot system is how incredibly easy it is to use. We've had welders with no robot experience pick it up and run a job within minutes — no lengthy training required. The feedback from our customers has been overwhelmingly positive. They love how it simplifies complex welding tasks and makes automation accessible, even for smaller shops."

Reimagining the User Experience

To test their concept, Miller’s engineering team built a bare-bones prototype. In this early set-up, a senior welder would write a script for a specific job, and then a junior welder would use the cobot arm to execute it – producing the needed pieces, whether 100 or 1,000. The prototype performed reliably, validating both the technical feasibility and the practical workflow of the system.

Buoyed by this success, Miller moved confidently into product development. They envisioned a user interface that was simple and intuitive enough for junior welders, yet still powerful and respectful of the expertise of seasoned professionals with years of domain knowledge.

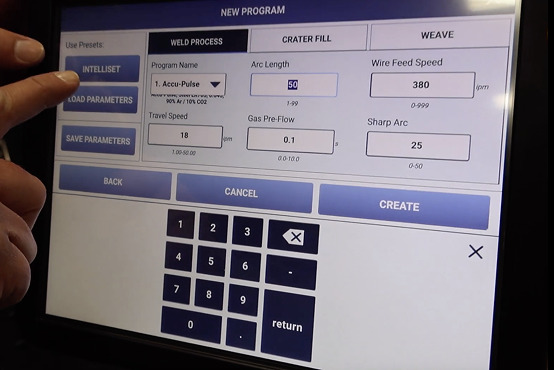

Facing a tight deadline and a critical user experience challenge, Miller turned to ICS’ UX design specialists to re-imagine the typical cobot control interface. We immersed ourselves in welding workflows to understand how welders interact with their tools and environment. Then, leveraging UX best practices we translated those insights into an interface that balances ease-of-use with flexibility – one so intuitive, even the most junior-level welder could learn to use the cobot almost immediately.

To achieve this balance, we restructured common welding tasks into streamlined, wizard-like dialogs that gently guide users through each step without locking them into rigid paths. Advanced options remain just one tap away, preserving expert-level control for welders with years of experience.

"Miller had the vision and welding expertise, but we needed help to create a user-friendly interface. That's where ICS stepped in. They were not only reliable and easy to work with but also demonstrated what true partnership and collaboration look like. With their innovative ideas, ICS helped Miller develop an interface that differentiated our product."

Speeding Development with ICS’ HMI Accelerator

To quickly gather early market feedback, the initial release was intentionally limited in scope. As a Minimum Viable Product (MVP), it delivered only the core functionality needed to validate Miller’s innovative approach. We met an aggressive timeline by leveraging ICS’ HMI Accelerator, which expedites development by converting UX designs directly from Figma into working code. This allows for faster prototyping, earlier testing and speedy iteration to refine the product.

To quickly gather early market feedback, the initial release was intentionally limited in scope. As a Minimum Viable Product (MVP), it delivered only the core functionality needed to validate Miller’s innovative approach. We met an aggressive timeline by leveraging ICS’ HMI Accelerator, which expedites development by converting UX designs directly from Figma into working code. This allows for faster prototyping, earlier testing and speedy iteration to refine the product.

Miller took the MVP to a series of industry trade shows where welders and shop owners immediately recognized the system’s potential: a welding cobot that wasn’t just powerful, but actually usable in their work environment. Buoyed by the enthusiastic response, ICS and Miller entered the next phase of development: adding and refining features based on customer input, and expanding the product line.

Today, the Miller® Copilot™ Welding Automation System is a market leader in its niche. This category-defining system now includes two distinct products: Miller Copilot™ – a fixed, tabletop system ideal for repetitive small-part welding, and Copilot™ Builder™ – a flexible version mounted to a movable cart or wall, perfect for field or on-site applications. Both products have been purpose-built to simplify automation, boost productivity and maintain a high degree of weld quality without the steep learning curve characteristic of other robotic systems.

A Partnership Built on Creativity and Trust

The collaboration between ICS and Miller was a study in effective partnership. Miller’s team brought engineering excellence, visionary thinking and an open mind, while ICS added deep UX expertise and advanced, rapid-development capabilities. Together, we built something that is transforming how small welding shops operate – and empowering the next generation of welders by expanding access to automation.

"Working with the Miller team was incredibly rewarding. They brought deep domain expertise and a clear vision, but what really made the collaboration fruitful was their openness to new ideas. They trusted ICS to push the boundaries on UX and development, which gave us the freedom to innovate. That level of mutual respect and flexibility is what turned a promising prototype into a truly market-leading product."

About Miller

Wisconsin-based Miller Electric Mfg. LLC is a leading manufacturer of welding equipment. Its Copilot™ Automated Welding System stands out for its ease of use, advanced automation features, and robust design tailored for shops new to robotic welding. Its intuitive controls, process support and seamless integration with Miller’s ecosystem make it a compelling choice for businesses seeking to boost productivity and weld quality without the complexity or steep learning curve of traditional robotic systems.