Mevion Medical Systems

Giving cancer the boot

ICS Helps Mevion Expand Access to Lifesaving Cancer Treatment

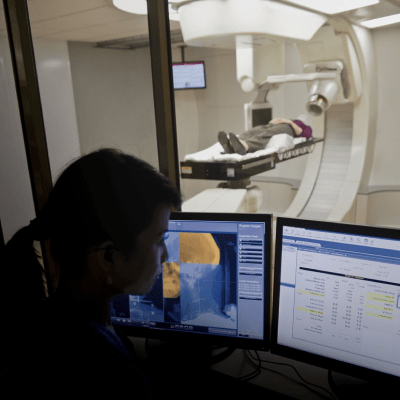

Mevion Medical Systems provides radiation therapy systems used to treat cancer. The company’s flagship product, the MEVION S250™ Proton Therapy System, makes proton therapy available to more patients by lowering the cost of the treatment dramatically. Previously available systems required a special facility the size of a football field and cost up to $100M to build and maintain. The MEVION S250, with a much lower price tag of $25M, fits in a building the size of an existing radiation treatment center.

Proton therapy is an advanced form of radiation treatment that allows physicians to target tumors more precisely than conventional high-energy X-rays. X-rays reach their peak dose shortly after penetrating tissue, whereas protons emit only a small amount of energy until they reach their “target depth,” which is determined by a physician based on the location, size and shape of the tumor. Using proton therapy, physicians can precisely deliver the dose while greatly reducing exposure to surrounding healthy tissue.

Today, proton therapy is most often ordered for children and for adults with tumors adjacent to the eyes, brain and other particularly critical sites. While the benefits of proton therapy have been understood for some time, the treatment’s availability has been limited by the size and cost of the facility required to house the equipment, the cost of the equipment itself and the complexity of delivering the treatment.

The MEVION S250 is much smaller and far less expensive than existing systems, removing two important obstacles to widespread availability.

The MEVION S250 is built around the world’s first superconducting synchrocyclotron, a high-energy proton source that powers a system that is not only smaller and less expensive than previous systems, but also more reliable and precise. The system also incorporates a number of innovations that combine to reduce the complexity of delivering proton treatment to patients, including:

The MEVION S250 is built around the world’s first superconducting synchrocyclotron, a high-energy proton source that powers a system that is not only smaller and less expensive than previous systems, but also more reliable and precise. The system also incorporates a number of innovations that combine to reduce the complexity of delivering proton treatment to patients, including:

- A much smaller high-energy proton source

- Advanced beam delivery and shaping technology

- Seamless integration with oncology information and treatment planning systems

- A 6 degree of freedom robotic couch to position the patient for treatment

- A 2D/3D radiographic imaging system

- In-room CT imaging system

The MEVION S250 combines all of these innovations in a clinical environment that resembles a conventional radiation treatment room, paving the way for health systems to offer the benefits of proton therapy to more patients.

Developing the Software to Power Mevion S250

Nearly every piece of the new system requires software development, and those systems need to work together. Software required for the MEVION S250 includes:

- Service screen, which is used by Mevion’s physicists, service personnel and other employees to test and commission the system prior to clinical use

- Patient positioning system to relate stored imaging data to the patient on the couch, creating a 2D/3D transformation that can be used iteratively to position the patient

- Therapy console used by the therapists to deliver and track the treatment plan and integrate to third-party systems within the hospital

- Embedded systems that perform data acquisition and control all low level subsystems, including but not limited to the dosimetry system, concentric gantry system, and field shaping system used to deliver the beam

Together, these systems present a distributed environment that includes Windows®, Linux® and VXworks® operating environments. Mevion chose the Qt™ application framework because it provides a widget toolkit for developing graphic applications across all of these operating systems, as well as important non-GUI features like XML parsing, thread management and network support. Developing with Qt allowed Mevion to use the code they created across these diverse systems, providing consistency and making development more efficient.

The MEVION S250’s software systems must be validated according to the FDA regulations, which require comprehensive testing as well as finding, tracking and resolving software defects. Validating these systems requires an enormous commitment of resources, but staying on schedule for FDA approval is critical. Mevion brought ICS in to assist in completing the software development and testing to ensure a timely filing for FDA clearance.

"We hired ICS because they are the Qt experts, but we have also benefited greatly from their depth of expertise in C++ as is related to our Windows, Linux and VXworks platforms. ICS helped us meet our deadline for FDA submission, but that was just the beginning of our relationship. The ICS engineers delivered the goods, earning the respect of our developers with their relentless focus on solving problems and getting things done."

The ICS engineers brought deep experience with complex systems, regulated environments and debugging multithreaded applications and quickly became valuable members of Mevion’s software SCRUM team. ICS consultants are trained to develop software using an agile process and were helpful during Mevion’s transition to three-week code sprints. ICS is proud of its role in developing the system and in doing so, helping to make a life-saving treatment more widely available to cancer patients who can benefit from it.

“The ICS team brought a wide range of software development skills and experience to the MEVION S250, and we valued those skills highly. Just as importantly, though, they brought a great attitude. When they ran into an obstacle, they figured out how to move past it. They understood our goal, and made it their goal, and they worked hard and worked smart to help us reach the goal together.”

About Mevion Medical Systems

![]()

Mevion Medical Systems, Inc. is a radiation therapy company dedicated to advancing the treatment of cancer. As the pioneering developer of modern proton therapy systems, Mevion provides innovative, safe, and effective solutions by transforming advances in medical technology and science into practical clinical realities. Visit www.mevion.com for more info.